Overview

At Baxtel Alloys, we understand that industrial reliability begins with the right materials. In Mumbai’s fast-paced manufacturing ecosystem, 316 stainless steel round bars have become a cornerstone for industries demanding corrosion resistance, strength, and long-term performance. As one of the leading manufacturers and suppliers in this space, we take pride in delivering products that meet the highest standards of quality and consistency. Our commitment goes beyond production, we build partnerships rooted in trust, technical expertise, and responsive service.

What Makes 316 Stainless Steel Exceptional?

316 stainless steel is an austenitic alloy known for its superior resistance to corrosion, especially in chloride-rich environments. The addition of molybdenum enhances its ability to withstand pitting and crevice corrosion, making it ideal for marine, chemical, and pharmaceutical applications. Unlike 304 stainless steel, 316 offers better durability in aggressive settings, including coastal infrastructure and acidic processing environments. Its non-magnetic nature and excellent weldability further expand its versatility across industries. We manufacture round bars that retain these properties consistently, batch after batch.

Applications That Demand 316 Round Bars

Our 316 stainless steel round bars are engineered for environments where failure is not an option. From offshore platforms and desalination plants to food-grade machinery and surgical equipment, these bars perform reliably under pressure. In Mumbai, we’ve seen growing demand from sectors like petrochemicals, construction, and water treatment. The alloy’s ability to maintain structural integrity in high-temperature and corrosive conditions makes it a preferred choice for valves, flanges, fasteners, and precision components. We tailor our offerings to meet the specific needs of each application.

Why Mumbai Is the Right Place to Source Stainless Steel

Mumbai’s industrial landscape is dynamic, diverse, and deeply connected to global supply chains. With proximity to major ports, access to skilled labor, and a thriving network of engineering firms, the city has become a hub for stainless steel manufacturing. We’ve built our operations here to leverage these advantages while staying close to our customers. Whether it’s a small fabrication shop in Navi Mumbai or a large-scale refinery in Thane, we ensure timely delivery and technical support. Our location allows us to respond quickly to market demands and maintain competitive pricing.

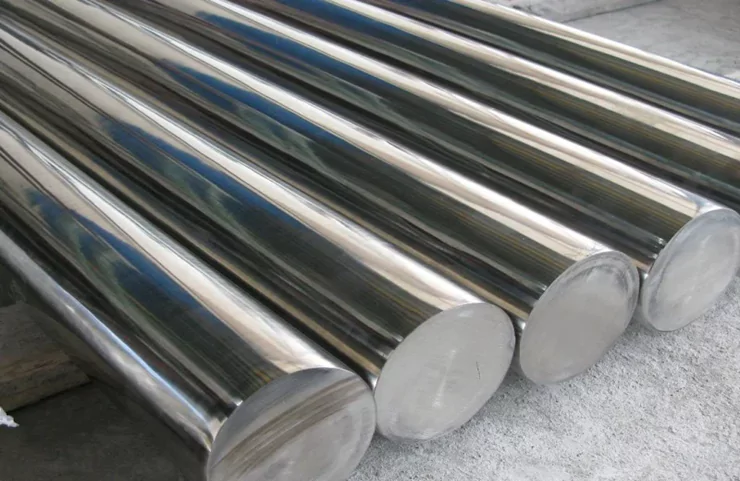

Our Manufacturing Capabilities at Baxtel Alloys

We specialize in producing high-quality 316 stainless steel round bars using advanced manufacturing techniques and rigorous quality control. Our facilities are equipped to handle a wide range of sizes, finishes, and custom specifications. In addition to round bars, we offer wire rods, filler wires, pipes, tubes, sheet plates, coils, angles, channels, valves, gaskets, flats, fasteners, flanges, and pipe fittings. Every product is crafted to meet national and international standards, ensuring performance and reliability. We don’t just manufacture, we engineer solutions that last.

Technical Specifications That Matter

Our 316 round bars are available in diameters ranging from 3mm to 200mm, with options for hot-rolled, cold-drawn, and polished finishes. We adhere to ASTM A276 and ASME SA479 standards, ensuring compatibility with global engineering requirements. The bars exhibit tensile strengths above 515 MPa and yield strengths around 205 MPa, with excellent elongation and hardness profiles. We also offer customization for length, tolerance, and surface treatment based on project needs. These specifications are not just numbers, they’re a reflection of our precision and commitment.

Quality Assurance Is Our Foundation

At Baxtel Alloys, quality is not negotiable. Every round bar undergoes rigorous testing, including ultrasonic inspection, chemical analysis, mechanical testing, and dimensional verification. We work with recognized third-party agencies to validate our results and provide full traceability for each batch. Our internal QA team ensures that every product meets the required standards before it leaves our facility. This attention to detail has earned us repeat business from clients across India and abroad. We believe that quality assurance is not a department, it’s a mindset.

Logistics and Delivery That Keep Projects Moving

Timely delivery is critical in industrial operations, and we’ve built our logistics system to support that. Whether supplying to a fabrication yard in Bhiwandi or shipping overseas, we ensure that our packaging, documentation, and transport meet client expectations. Our export-grade packaging includes wooden boxes, HDPE wrapping, and clear labeling for easy handling. We maintain buffer stock for high-demand items and offer flexible lead times for custom orders. Our logistics team works closely with clients to avoid delays and keep projects on track.

Choosing the Right Manufacturer

Selecting a stainless steel manufacturer is about more than price, it’s about trust, consistency, and long-term value. At Baxtel Alloys, we combine technical expertise with a customer-first approach. Our team is available to guide material selection, provide documentation, and ensure compliance with project specifications. We don’t just sell products, we build relationships. Our transparent pricing, certified quality, and responsive support make us a preferred partner for engineers, procurement teams, and project managers across Mumbai.

Global Standards That Define 316 Stainless Steel

When we manufacture 316 stainless steel round bars, we align with globally recognized standards to ensure consistency and performance. Specifications like ASTM A276 and ASME SA479 guide our production processes, from chemical composition to mechanical properties. These standards are not just paperwork, they’re the backbone of international compatibility and engineering trust. For a deeper understanding of how these standards shape the alloy’s behavior, we recommend exploring the complete technical overview of 316 stainless steel provided by Shalco. It offers valuable insights into metallurgy, corrosion resistance, and real-world applications.

Engineering Insights into 316 Stainless Steel Applications

Understanding where and how 316 stainless steel performs best helps us tailor our products to meet specific industrial needs. The alloy’s resistance to pitting and crevice corrosion makes it indispensable in marine environments, chemical processing, and medical-grade equipment. Its mechanical strength and weldability also support structural applications in high-stress conditions. For engineers and designers seeking a comprehensive breakdown, Baetro Machining’s Ultimate Guide to Stainless Steel 316 offers a well-rounded look at its properties, benefits, and use cases across industries.

International Equivalents and Grade Comparisons

While we manufacture to Indian and ASTM standards, we also understand the importance of international equivalents for global clients. Grades like EN 1.4401 (Europe), JIS SUS316 (Japan), and DIN X5CrNiMo17-12-2 (Germany) share similar compositions but may vary slightly in carbon or nitrogen limits. These differences can impact weldability and corrosion resistance in specific environments. For those comparing grades across regions, Metal Zenith’s overview of 316 stainless steel properties and key applications provides a clear breakdown of standards, equivalents, and performance benchmarks.

Sustainability and Long-Term Value

Sustainability is no longer a buzzword, it’s a responsibility we take seriously. Our 316 stainless steel round bars are designed for longevity, reducing the need for frequent replacements and minimizing material waste. The alloy’s resistance to corrosion and mechanical wear means fewer breakdowns and lower maintenance costs over time. We also follow environmentally conscious manufacturing practices, optimizing energy use and minimizing scrap. By choosing durable materials and efficient processes, we help our clients meet both performance goals and sustainability benchmarks. Long-term value isn’t just about cost, it’s about reliability and responsibility.

Customization for Complex Projects

No two projects are alike, and we thrive on meeting unique challenges with tailored solutions. Whether it’s a specific diameter, surface finish, or tolerance requirement, we offer customization that aligns with engineering demands. Our team collaborates closely with clients to understand the application, environment, and performance expectations before recommending the right configuration. We’ve supported everything from high-precision medical components to large-scale structural reinforcements. Flexibility is built into our process, and we’re equipped to deliver both small batches and bulk orders with the same attention to detail. Custom doesn’t mean complicated, it means committed.

Our Commitment to Technical Support

We believe that great products deserve great support. From material selection to post-delivery documentation, our technical team is available to assist at every stage. We provide detailed datasheets, compliance certificates, and testing reports to ensure transparency and confidence. For clients navigating complex specifications or international standards, we offer guidance that simplifies decision-making. Our support doesn’t end with the sale, it continues through installation, inspection, and beyond. At Baxtel Alloys, technical expertise is part of the package, not an add-on. We’re here to make stainless steel sourcing smarter, smoother, and more dependable.

FAQs: Nickel 200 Round Bar Manufacturers

Q.1: What is 316 stainless steel used for?

Ans. It’s widely used in marine, chemical, pharmaceutical, and food processing industries due to its corrosion resistance and durability.

Q.2: Are our products certified?

Ans. All our stainless steel products are tested and certified by recognized agencies to meet ASTM and ASME standards.

Q.3: Can we handle bulk orders?

Ans. Absolutely. We support both large-scale industrial orders and smaller project-based requirements with consistent quality and timely delivery.

Conclusion

At Baxtel Alloys, we don’t just manufacture stainless steel, we engineer reliability. Our 316 stainless steel round bars are crafted to meet the demands of Mumbai’s diverse industrial sectors, from marine infrastructure to chemical processing. With every order, we deliver more than just material, we deliver precision, consistency, and a commitment to long-term performance. Our team stands behind every product with technical expertise, responsive service, and a deep understanding of what drives industrial success. Whether it’s a custom specification or a bulk requirement, we’re ready to support projects that demand excellence. Let’s build something enduring, together.

Contact us today at +91-9137335305 |

Visit baxtelfasteners.com

to explore our full product range or request a custom quote.