Introduction

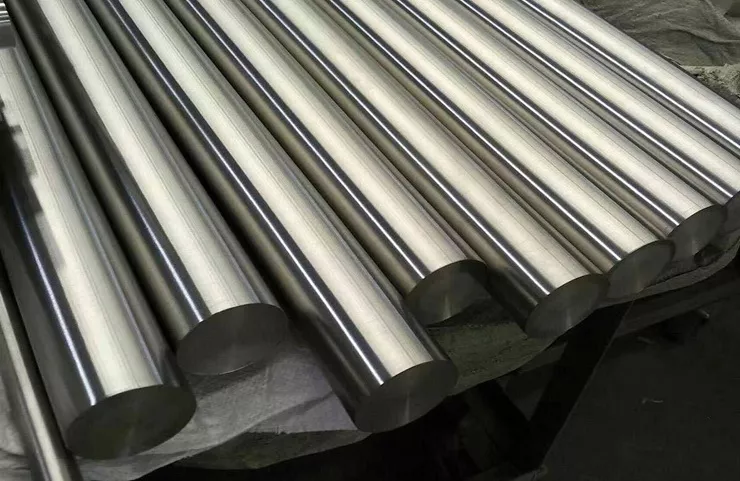

At Baxtel Alloys, we specialize in manufacturing high-quality 430 stainless steel round bars that meet the evolving demands of modern industries. Based in Mumbai, we’ve built our reputation on precision, reliability, and a deep understanding of metallurgical performance. Our 430 SS round bars are engineered for durability and corrosion resistance, making them ideal for a wide range of applications. Whether it's for structural integrity, aesthetic appeal, or mechanical strength, we deliver products that consistently exceed expectations. We take pride in being one of the most trusted names in the stainless steel manufacturing space, serving clients across India and beyond.

What Makes 430 Stainless Steel Unique?

430 stainless steel belongs to the ferritic family, known for its excellent resistance to oxidation and stress corrosion cracking. It contains chromium as the primary alloying element, which enhances its ability to withstand high temperatures and corrosive environments. Unlike austenitic grades, 430 does not contain nickel, making it more cost-effective while still offering solid performance. We manufacture these round bars with tight tolerances and smooth finishes to ensure they meet both functional and aesthetic requirements. Our clients appreciate the balance of affordability and strength that 430 SS offers, especially in applications where welding and extreme corrosion resistance are not critical.

Applications Across Industries

Our 430 stainless steel round bars are used in a wide variety of industries, each with its own set of performance demands. In the automotive sector, they’re commonly found in trim and exhaust systems due to their heat resistance. Construction companies rely on them for structural components that require longevity and minimal maintenance. We also supply to manufacturers of kitchen equipment, where hygiene and corrosion resistance are essential. From fabrication shops to infrastructure projects, our round bars provide the consistency and reliability that professionals need. We work closely with engineers and procurement teams to ensure our products align with their technical specifications.

Why Mumbai Is the Ideal Manufacturing Hub

Operating out of Mumbai gives us a strategic advantage in terms of logistics, talent, and access to raw materials. The city’s industrial ecosystem is robust, with a well-established supply chain that supports everything from sourcing to distribution. We benefit from proximity to major ports, which allows us to serve international clients with ease. Mumbai’s skilled workforce and engineering expertise also enable us to maintain high production standards. Being part of this dynamic environment helps us stay agile and responsive to market trends. It’s not just about location, it’s about being part of a community that values innovation and quality.

Our Manufacturing Capabilities

At Baxtel Alloys, we’ve invested in state-of-the-art machinery and quality control systems to ensure every round bar meets rigorous standards. Our production facility is equipped to handle both large-scale orders and custom specifications. We offer a range of diameters, lengths, and surface finishes to suit diverse applications. Our team of metallurgists and engineers oversees every stage of production, from raw material selection to final inspection. We also maintain detailed documentation and traceability for every batch, giving our clients confidence in the integrity of our products. Quality isn’t just a goal, it’s embedded in our process.

Commitment to Quality and Compliance

We adhere to international standards such as ASTM, DIN, and JIS, ensuring our products are compatible with global engineering requirements. Our quality assurance team conducts rigorous testing, including tensile strength, hardness, and chemical composition analysis. We also offer third-party inspection options for clients who require additional verification. Certifications and compliance are more than paperwork for us, they’re a reflection of our commitment to excellence. We continuously upgrade our processes to meet evolving industry norms and client expectations. Every round bar that leaves our facility is a testament to our dedication to precision and reliability.

Choosing the Right Manufacturer Matters

Selecting a stainless steel round bar manufacturer is a critical decision that impacts product performance, project timelines, and long-term costs. We encourage clients to look beyond price and consider factors like material integrity, delivery reliability, and technical support. At Baxtel Alloys, we offer all three. Our transparent communication, responsive service, and engineering expertise set us apart. We don’t just supply steel, we build partnerships that last. Whether the requirement is standard or custom, we approach every project with the same level of commitment and attention to detail.

Why Baxtel Alloys Is the Preferred Choice

Our clients choose us because we combine technical excellence with a customer-first mindset. We offer competitive pricing without compromising on quality. Our logistics team ensures timely delivery across India and to international destinations. We also provide post-sales support, helping clients troubleshoot and optimize their applications. With over a decade of experience, we’ve built a reputation for reliability and innovation. Our goal is not just to be a supplier, but a strategic ally in our clients’ growth. When industries need stainless steel that performs under pressure, they turn to Baxtel Alloys.

Metallurgy Behind 430 Stainless Steel

We base our production of 430 stainless steel round bars on a clear understanding of ferritic metallurgy and how it translates to end-use performance. The ferritic crystal structure gives 430 good resistance to oxidation and moderate corrosion resistance while retaining magnetic properties. Because 430 contains chromium but no nickel, we can offer a cost effective alternative where high nickel alloys are not required. Our process controls focus on achieving consistent chemical composition and grain structure so mechanical properties remain predictable across batches. Heat treatment is not used to harden this grade, so we emphasize cold working and precise machining to meet dimensional tolerances. We monitor carbon, chromium, and other trace elements closely to prevent sensitization and preserve formability. For a thorough technical overview of ferritic stainless steels we reference the detailed entry on Wikipedia to align our material selection with established metallurgical principles.

Stainless Steel Demand in India Industrial Growth

We monitor market movements and see steady demand for stainless steel from infrastructure, automotive, and appliance manufacturers across India. Urbanization and investments in transport and energy projects have increased the need for corrosion resistant materials, which keeps demand for grades like 430 robust. Mumbai’s logistics network and industrial ecosystem make it easier for us to serve both domestic projects and export orders without compromising lead times. We translate macroeconomic indicators into production plans so we can scale output during peak periods and avoid supply bottlenecks. Close relationships with raw material suppliers help us maintain price stability and ensure continuity of supply. For a snapshot of broader market signals and search interest that influence procurement cycles we consult market trend searches on Google to inform our planning and customer guidance.

Baxtel Alloys on IndiaMART

We maintain an active presence on IndiaMART to make product specifications, datasheets, and inquiry options readily available for procurement teams. Listing our 430 stainless steel round bars on a leading B2B marketplace helps interested buyers view available sizes, finishes, and minimum order quantities at a glance. Through the platform we handle RFQs, share inspection reports, and coordinate logistics details for both domestic and international shipments. Keeping our IndiaMART listing current enables us to respond quickly to buyers who prefer marketplace sourcing workflows. We integrate marketplace leads with our CRM to ensure timely technical follow up and personalized quotations. IndiaMART also provides useful market signals that help us refine product offerings and service levels. View our category presence and related alloy listings on IndiaMART for a sense of how we present technical detail and procurement options online.

Technical Standards for 430 Stainless Steel Round Bars

We manufacture 430 stainless steel round bars to meet internationally recognized standards so the material integrates smoothly into engineered systems and approval processes. Conformance to specifications for chemical composition, mechanical properties, and dimensional tolerances is verified through routine tensile, hardness, and chemical analyses in our quality lab. We support third party inspections and provide mill test reports or certificates of conformity when contracts require independent verification and traceability documentation. Maintaining calibrated equipment and documented procedures is central to our quality management approach and continuous improvement efforts. Adhering to technical norms reduces installation risk and simplifies approvals for fabricators and regulators. When clients request specific standard references or compliance evidence we supply detailed paperwork that aligns with project and regulatory needs. For reference on grades and standards in stainless steel we align our internal practices with widely accepted guidance available on Wikipedia.

Sustainable Practices in Our Manufacturing

We prioritize sustainability across our production chain and continuously seek ways to reduce waste and energy consumption. We optimize raw material usage through careful planning and efficient nesting to minimize offcuts. Our facilities use energy efficient equipment and we track consumption to identify improvement opportunities. Recycled stainless steel is incorporated where technical requirements allow without compromising quality. Water used in cooling and finishing processes is treated and reused wherever possible to lower our environmental footprint. We engage with suppliers who follow responsible mining and material handling practices to promote a cleaner supply chain. Training programs for staff emphasize resource stewardship and operational efficiency as core values. We report progress internally and set measurable targets to ensure continuous improvement.

Technical Support and After Sales Service

We provide dedicated technical support from project specification through to post delivery troubleshooting to ensure successful application of our 430 round bars. Our engineering team assists with material selection, machining recommendations, and performance expectations under different service conditions. We supply detailed mill test reports and handling guidelines to simplify quality assurance at the client end. For special projects we coordinate on-site visits or remote consultations to resolve fit, finish, or installation concerns. Our logistics team tracks shipments and communicates proactively to avoid delays and manage any customs or documentation needs. We maintain a parts and rework policy to support warranty requests and minimize downtime for clients. Continuous feedback loops from after sales interactions inform product improvements and service enhancements. We view long term support as integral to building trust and repeat business.

FAQs: 430 Stainless Steel Round Bar Manufacturers

Q.1: Do we export internationally?

Ans. Yes, we ship domestically and internationally, leveraging Mumbai logistics to serve global clients efficiently.

Q.2: - Is 430 stainless steel magnetic and corrosion resistant?

Ans. 430 is ferritic and magnetic, offering good oxidation resistance and moderate corrosion resistance suitable for many industrial uses.

Q.3: - How can clients request a quote or technical consultation?

Ans. - Clients can contact us by phone at +91-9137335305 or visit https://baxtelfasteners.com to request a quote or technical support.

Conclusion

We deliver 430 stainless steel round bars with an unwavering focus on consistency, performance, and traceability. Our ferritic 430 grade provides a practical balance of corrosion resistance, heat tolerance, and cost effectiveness that meets the needs of diverse industrial applications. Operating from Mumbai gives us strategic logistical reach and access to skilled metallurgical expertise that supports both domestic and international projects. We maintain rigorous quality controls and adhere to recognized technical standards so every batch performs as specified in the field. Our production flexibility allows us to supply standard sizes as well as custom specifications for specialized requirements. Every shipment is accompanied by detailed documentation, testing data, and responsive technical support to ensure the material is fit for purpose. Partnering with us means working with a supplier that values long term performance, transparent communication, and on time delivery. Contact us at +91-9137335305 or visit https://baxtelfasteners.com to request a quote or discuss technical requirements.

Contact us today at +91-9137335305 |

Visit baxtelfasteners.com

to explore our full product range or request a custom quote.