Overview

At Baxtel Alloys, we understand that industrial-grade materials are more than just components—they’re the backbone of performance, reliability, and long-term value. Among our most trusted offerings, the bronze round bar stands out for its exceptional mechanical properties and versatile applications. Whether used in marine engineering, architectural detailing, or heavy-duty manufacturing, bronze round bars deliver a balance of strength, corrosion resistance, and machinability that few materials can match.

What Defines a Bronze Round Bar?

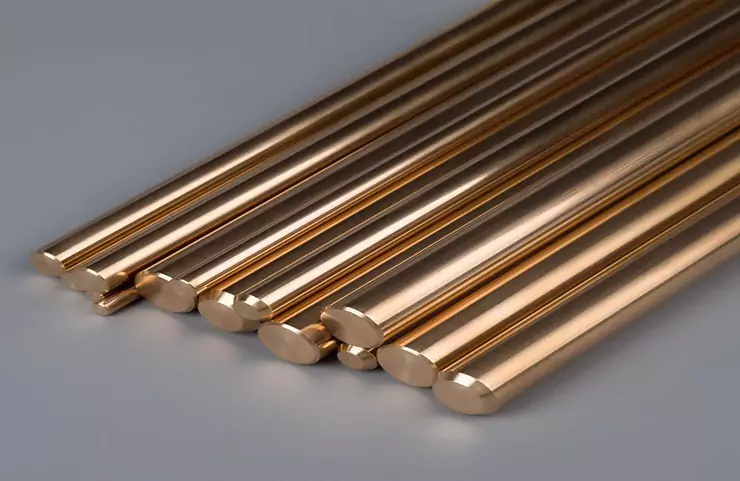

A bronze round bar is a solid cylindrical rod composed primarily of copper and tin, often alloyed with elements like aluminum, phosphorus, or silicon to enhance specific properties. Known for its excellent wear resistance and low friction characteristics, bronze is ideal for components that endure constant motion or exposure to harsh environments. Our bronze round bars are precision-engineered to meet stringent dimensional tolerances, ensuring seamless integration into complex assemblies. With a smooth surface finish and consistent grain structure, these bars offer superior machinability and aesthetic appeal. From small-scale fabrication to large industrial builds, bronze round bars provide the durability and flexibility needed for demanding applications.

Applications Across Industries

Bronze round bars are widely used across sectors that demand both strength and corrosion resistance. In marine environments, they serve as reliable components for propellers, shafts, and fittings due to their resistance to saltwater degradation. Architectural firms favor bronze for its warm tone and patina development, making it ideal for decorative railings, sculptures, and façade elements. In aerospace and defense, bronze is chosen for its non-sparking properties and dimensional stability under stress. Electrical engineers rely on bronze for connectors and terminals, while plumbing systems benefit from its antimicrobial qualities. Our bronze round bars are tailored to meet the diverse needs of these industries, ensuring consistent performance and long-term reliability.

Why Bronze Outperforms Other Alloys

Compared to brass, copper, or stainless steel, bronze offers a unique combination of mechanical strength and corrosion resistance. Its ability to withstand friction and wear makes it ideal for bushings, bearings, and gear components. Unlike stainless steel, bronze does not gall under pressure, which reduces maintenance and extends service life. While brass may offer aesthetic appeal, bronze surpasses it in tensile strength and durability. Copper, though highly conductive, lacks the structural integrity required for load-bearing applications. Our bronze round bars are engineered to outperform these alternatives, offering a cost-effective solution without compromising on quality or longevity.

Our Product Range and Customization Options

At Baxtel Alloys, we offer a comprehensive selection of bronze round bars in various diameters, lengths, and alloy grades to suit specific project requirements. In addition to round bars, our inventory includes wire rods, filler wires, pipes, tubes, sheet plates, coils, angles, channels, valves, gaskets, flats, fasteners, flanges, and pipe fittings. Each product is manufactured under strict quality control protocols to ensure consistency and compliance with international standards. We also provide customization options for clients requiring non-standard dimensions or specialized finishes. Whether for prototyping or mass production, our bronze round bars are available in bulk quantities with prompt delivery and competitive pricing.

Manufacturing Excellence and Quality Assurance

Our bronze round bars are produced using advanced casting and extrusion techniques that ensure uniformity and structural integrity. Every batch undergoes rigorous testing for chemical composition, tensile strength, and surface finish. We adhere to ISO and ASTM standards, and our facilities are equipped with state-of-the-art inspection tools to verify dimensional accuracy and defect-free surfaces. Quality assurance is embedded in every stage of production—from raw material selection to final packaging. Our team of metallurgical experts continuously monitors process parameters to maintain consistency and traceability. This commitment to excellence allows us to deliver bronze round bars that meet the highest expectations of performance and reliability.

Choosing the Right Bronze Round Bar

Selecting the appropriate bronze round bar depends on several factors, including the intended application, required mechanical properties, and environmental conditions. For high-load components, a higher tin content may be preferred to enhance strength. In corrosive settings, aluminum bronze offers superior resistance to oxidation and seawater. Our technical team is available to guide clients through the selection process, offering insights into alloy grades, machining behavior, and compatibility with other materials. We also provide detailed datasheets and consultation services to ensure optimal material choice. With our support, clients can confidently choose bronze round bars that align with their project goals and performance criteria.

Ordering Made Simple

We’ve streamlined the ordering process to ensure fast, hassle-free procurement of bronze round bars and related products. Clients can request quotes directly through our website or contact our sales team for personalized assistance. Our logistics network supports global shipping, with secure packaging and real-time tracking for every order. We also offer flexible payment options and volume discounts for bulk purchases. For urgent requirements, expedited delivery services are available. Reach out to us at +91-9137335305 or visit baxtelfasteners.com to explore our full catalog and place an order with confidence.

Global Standards and Compliance

Our bronze round bars are manufactured in accordance with internationally recognized specifications such as ASTM B62 and B694, ensuring consistent quality and performance across applications. These standards define the chemical composition, mechanical properties, and dimensional tolerances required for industrial-grade bronze. Adhering to such benchmarks allows us to serve clients across sectors with confidence and precision. For professionals seeking deeper insights, refer to ASTM’s official bronze alloy specification B62 and B694 for copper-clad bronze to understand the technical criteria used globally.

Bronze vs. Brass: What’s the Difference

Though visually similar, bronze and brass differ significantly in composition and performance. Bronze, primarily copper and tin, offers superior strength and corrosion resistance, especially in marine and industrial environments. Brass, made from copper and zinc, is more malleable and suited for decorative or low-load applications. Understanding these differences is essential for selecting the right material. For a comprehensive comparison, refer to Metal Supermarkets’ guide on copper, brass, and bronze.

Sustainability and Recycling of Bronze

Bronze is highly recyclable, making it a sustainable choice for modern manufacturing. Recycled bronze retains its mechanical properties, contributing to reduced environmental impact and lower production costs. At Baxtel Alloys, we support responsible sourcing and recycling practices across our supply chain. For insights into how copper-based alloys like bronze contribute to green building and circular economy goals, explore Copper.org’s overview of copper in sustainable construction.

Machinability and Fabrication Benefits

Bronze round bars offer excellent machinability, making them ideal for precision components that require tight tolerances and clean finishes. The alloy’s grain structure allows for smooth cutting, drilling, and shaping without excessive tool wear. This reduces production time and lowers operational costs, especially in high-volume manufacturing environments. Our bronze bars respond well to CNC machining, lathe work, and milling processes, ensuring consistent results across batches. Whether for bushings, couplings, or ornamental details, the ease of fabrication makes bronze a preferred choice among engineers and fabricators. We also offer pre-cut lengths and custom finishes to streamline integration into existing workflows.

Thermal and Electrical Conductivity

Bronze is known for its favorable thermal and electrical conductivity, making it suitable for components exposed to heat or requiring reliable current flow. While not as conductive as pure copper, bronze provides a balanced profile of strength and conductivity, which is ideal for electrical connectors, switchgear, and heat exchangers. Its ability to dissipate heat efficiently helps prevent warping or fatigue in high-temperature environments. Our bronze round bars are often used in applications where both mechanical integrity and conductivity are essential. This dual functionality allows for broader use across industries like power generation, electronics, and industrial automation.

Inventory Management and Supply Reliability

At Baxtel Alloys, we prioritize supply chain efficiency to ensure uninterrupted access to bronze round bars and related products. Our inventory is strategically managed to accommodate both standard and custom orders, with real-time tracking and responsive fulfillment. We maintain stock in multiple sizes and grades to support urgent requirements and long-term contracts. Our logistics team coordinates closely with clients to align delivery schedules with project timelines, minimizing downtime and material shortages. With a reputation for reliability and transparency, we’ve built lasting relationships across sectors that depend on consistent supply and proactive support.

FAQs About Bronze Round Bar

Q.1: Can bronze round bars be used in marine environments?

Ans. Yes, especially aluminum bronze grades, which offer excellent resistance to seawater corrosion.

Q.2: Do we provide test certificates with each order?

Ans. Yes, material test certificates are included to ensure compliance and traceability.

Q.3: Can we request alloy-specific recommendations?

Ans. Yes, our technical team provides guidance based on application, environment, and performance needs.

Conclusion

Bronze round bars continue to be a cornerstone material across industries that demand durability, precision, and corrosion resistance. At Baxtel Alloys, we combine metallurgical expertise with a commitment to quality, ensuring that every bronze bar we supply meets the highest standards of performance. From marine engineering to architectural detailing, our products are trusted to deliver long-term value and reliability. With a wide range of grades, sizes, and customization options, we’re equipped to support projects of every scale. Backed by responsive service and global logistics, our bronze round bars are more than just materials—they’re a promise of excellence. Explore our full catalog and let our team help you build with confidence.

Contact us today at +91-9137335305 |

Visit baxtelfasteners.com

to explore our full product range or request a custom quote